We Make Smart Manufacturing a Reality

Purpose-built for manufacturing: the Accella AI suite of products enables the easy, fast and economical implementation of AI-based solutions on the shopfloor

Improve Manufacturing Efficiency and Reduce Cost with AI

What our Customers Say

Not only are we going to roll out this solution worldwide, we are also planning on adding more AI-powered quality check points and predictive maintenance applications.”

Leverage your personel and reduce cost with Accella AI Solutions custom build for Manufacturing

Manufacturers are under tremendous pressure to achieve more – better quality, faster production – with less (money, people, time). Traditional approaches to incremental improvement and lean manufacturing do not achieve the needed improvements anymore. New solutions based on AI promise to deliver against the challenging triple goal of better, faster, cheaper. At Accella AI we develop solutions that help manufacturers of all sizes make smart manufacturing a reality.

The Accella AI Bot platform allows manufacturers to develop, deploy and coordinate AI models for applications in manufacturing such as quality control, predictive maintenance and predictive analytics and HMI simplification. It also orchestrates data collected from all devices and sensors, e.g. cameras, thermometers, vibration, and analyze them.

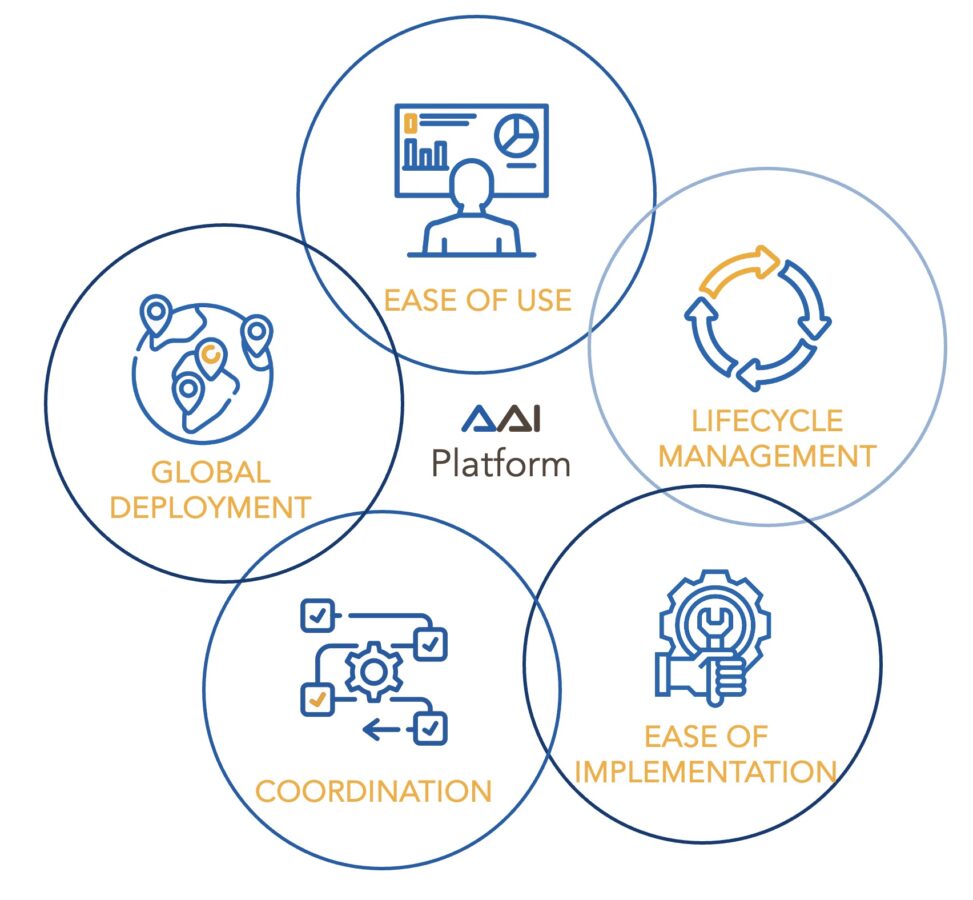

The Accella AI Bot platform is designed for:

- Ease of use with a GUI designed for engineers and technicians on the shopfloor

- Fast global deployment with automated hardware set-up and roll-out

- Intuitive lifecycle management of AI models incl. deployment, retraining and decommission

- Fast, cheap, reliable and low-risk implementation within weeks

- Coordination of 100 or even 1,000s of models and devices so they work together without performance issues

One Platform for all AI on the Shopfloor

Solutions for Manufacturing

We focus exclusively on AI solutions for manufacturing

Quality

Control

Use AI to inspect your products at any stage during manufacturing. Detect and classify defects with great accuracy.

Predictive

Maintenance

Train the model with sensor data from the line, maintenance logs, error messages and environmental data to establish reliable estimates of the remaining useful life of critical equipment.

Other

Solutions

Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum

We work with you to:

- Reduce equipment downtime

- Reduce scrap

Improve quality of products - Improve equipment health

- Optimize maintenance strategy

We work collaboratively with our customers. Our goal is to ease organizations into using AI in their manufacturing operations and empower them to develop the in-house capabilities to implement additional solutions with existing resources.

Find out how we work with our customers.